Hello Everyone,

Of course, we haven't forgotten about our other upcoming events, and I'm very pleased to announce that we have some new sponsors join us. TOMRA Sorting Solutions have agreed to support Physical Separation '19 for the 4th time, whilst Outotec are sponsoring it for the first time - after showing their support previously as sponsors for many of our other events. Then later in the year, we have Flotation '19. Kemtec are the 13th sponsor of this event, having sponsored once before in 2017.

Looking ahead to 2020, ME Elecmetal are sponsoring Comminution '20 for the first time, although with 18 months still to go before the event, they are already the 9th sponsor! It looks like Comminution '20 is on course to be as popular as ever.

As mentioned in the last newsletter, we are trying to build our subscriber list back up. If you wish to be added to the list for future newsletters, please let me know.

Analytical Techniques & Applied Mineralogy

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

* Technical Programme: Process Mineralogy '18

* Register Now: Process Mineralogy '18

* Recently Refereed Publications:

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Analytical Techniques & Applied Mineralogy is sponsored by FEI

Biotechnology

~~~~~~~~~

* First Announcement: Biomining '20

* The Environmental Applications of Biotechnology in Mining

* Recently Refereed Publication:

Minerals Engineering Vol.126

Comminution

~~~~~~~~~

* First Announcement: Comminution '20

* Peak Performance from Metso's new Superior MKIII Primary Gyratory Crusher

* Metso to Deliver Comminution and Material Handling Solutions to Australia and South America

* Conference Announcement: ESCC 2019

* Recently Refereed Publications:

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Powder Technology Vol.337

Comminution is sponsored by Russell Mineral Equipment

Computer Applications

~~~~~~~~~~~~~~~

* Call for Papers: Computational Modelling '19

* Recently Refereed Publications:

Powder Technology Vol.338

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Powder Technology Vol.337

Environmental Issues

~~~~~~~~~~~~~~

* First Announcement: Sustainable Minerals '20

* Technical Programme: Hi-Tech Metals '18

* Register Now: Hi-Tech Metals '18

* Conference Announcement: The 9th International Conference on Sustainable Development in the Minerals Industry

* The Environmental Applications of Biotechnology in Mining

* Recently Refereed Publications:

Minerals Engineering Vol.126

Separation and Purification Technology Vol.206

Minerals Engineering Vol.125

Froth Flotation

~~~~~~~~~~

* First Announcement: Flotation '19

* World’s Largest Flotation Cells Improve Copper and Molybdenum Recovery in Mexico

* Are Conditioning Tanks Making A Comeback?

* Commencement of Flotation Commissioning at the Hellyer Polymetallic Project, Tasmania

* Recently Refereed Publications:

Powder Technology Vol.338

Minerals Engineering Vol.126

Separation and Purification Technology Vol.206

Colloids and Surfaces A: Physicochemical and Engineering Aspects Vol.555

Chemical Engineering Journal Vol.351

Minerals Engineering Vol.125

Froth Flotation is sponsored by FLSmidth

General Minerals Engineering

~~~~~~~~~~~~~~~~~~~

* Technical Programme: Hi-Tech Metals '18

* Register Now: Hi-Tech Metals '18

* Conference Announcement: MetPlant 2019

* Conference Announcement: IMPC 2020

* Conference Announcement: COM 2019

* Conference Report: 2nd Young Nonferrous Metals Scientists & Engineers Forum

* High Capacity Microwave Treatment of Ores may be Closer than we Thought

* CIM Awards - Call for Nominations

* Eriez Europe Expands With New Manufacturing Facility

* ArcelorMittal Mining Canada G.P. to Fund Major Mining Research Collaboration at McGill University

* Recently Refereed Publications:

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Gravity Concentration

~~~~~~~~~~~~~~

* Call for Papers: Physical Separation '19

* Tempo Mineral Processing Offers DMS Cyclone Refurbishment Service

* Recently Refereed Publications:

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Hydrometallurgy

~~~~~~~~~~~

* First Announcement: Biomining '20

* The Environmental Applications of Biotechnology in Mining

* Lithium Ion Exchange Provides a New Source for Battery Materials

* Recently Refereed Publications:

Chemical Engineering Journal Vol.354

Minerals Engineering Vol.126

Separation and Purification Technology Vol.207

Minerals Engineering Vol.125

Chemical Engineering Science

Journal of Cleaner Production Vol.197

Magnetic/Electrical Separation

~~~~~~~~~~~~~~~~~~~~

* Call for Papers: Physical Separation '19

* Innord Approved for Conditional Funding from the National Research Council of Canada

* Recently Refereed Publications:

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Materials Handling

~~~~~~~~~~~~

* Recently Refereed Publication:

Powder Technology Vol.338

Pyrometallurgy

~~~~~~~~~~~~

* RNC's Innovative Roasting Approach Delivers 25% Increase In Payable Nickel Value For Nickel Sulphide Concentrates

Reagents

~~~~~~

* AkzoNobel Specialty Chemicals is now Nouryon

* Recently Refereed Publications:

Powder Technology Vol.338

Minerals Engineering Vol.126

Separation and Purification Technology Vol.207

Minerals Engineering Vol.125

Reagents is sponsored by Axis House

Sizing, Classification & Sorting

~~~~~~~~~~~~~~~~~~~~

* Call for Papers: Physical Separation '19

* TOMRA Enhances X-TRACT with Dual Processing Technology, Multi-Density Channels, and Application Packages

* Large New TOMRA X-ray Sorter

* Recently Refereed Publications:

Powder Technology Vol.338

Minerals Engineering Vol.126

Separation and Purification Technology Vol.206

Solid-Liquid Separation

~~~~~~~~~~~~~~~

* Call for Papers: Physical Separation '19

Solid-Liquid Separation is sponsored by FLSmidth

Plant Operations

~~~~~~~~~~~

* Investment in Leaching Plant at Boliden Rönnskär

* World’s Largest Flotation Cells Improve Copper and Molybdenum Recovery in Mexico

* First Aachen Shear Reactor for Turkey

* BacTech Attracts Ecuador Partner for Ponce Enriquez Project

* Mineworx Provides Update on E-Waste Concentration Plant

* Multotec Samplers Give Real-Time Results at Gamsberg

* Metso to Deliver Beneficiation Solutions for Potash Industry in Belarus

* China's Western Mining to Launch Qinghai Copper Smelter Next Month

Plant Operations News Australasia is sponsored by Magotteaux

Plant Operations News Europe is sponsored by Holman-Wilfley

People News

~~~~~~~~

* Prof. Yuehua Hu Elected to Editorial Advisory Board of Minerals Engineering

* Prof. TC Rao Honoured as the “Father of Indian Minerals Engineering”

* Leagold Appoints Attie Roux as Chief Operating Officer

* A Brief but Enlightening Visit to China's Central South University

* 2018 CEEC Medal Winners Recognised At AusIMM Conference

* MEI's Barry Wills Appointed Honorary Professor of Central South University, China

* New Vice President of Technical Services for Canada’s Hudbay Minerals

* New Gold Announces Appointment of President and CEO

* J. Burgess Winter 1933-2018

* Major IMPC Awards to Two Distinguished American Professors

* IMA Medal of Excellence in Mineralogical Services 2017 goes to Emil Makovicky

* John Van Nostrand Dorr joins the IM Technology Hall of Fame: Concentration

Join the Minerals Engineers LinkedIn Group

People News Australia is sponsored by JKMRC & JKTech

Commodities

~~~~~~~~~

New items in:

* Calcium Carbonate - Refereed Publications

* Cobalt - Refereed Publications

* Copper - News

* Copper - Conference Announcements

* Copper - Refereed Publications

* Gold - News

* Gold - Refereed Publications

* Iron - Conference Announcements

* Iron - Refereed Publications

* Kaolin - Refereed Publications

* Lithium - News

* Lithium - Refereed Publications

* Manganese - Refereed Publications

* Nickel - News

* Nickel - Refereed Publications

* Platinum Group Metals - Refereed Publications

* Potash - News

* Quartz - Refereed Publications

* Rare Earths & Thorium - News

* Rare Earths & Thorium - Refereed Publications

* Titanium - Refereed Publications

* Tungsten - Refereed Publications

* Vanadium - Refereed Publications

* Zinc - Refereed Publications

Minerals Engineering Conferences

~~~~~~~~~~~~~~~~~~~~~~

* Technical Programme: Process Mineralogy '18

* Register Now: Process Mineralogy '18

* Technical Programme: Hi-Tech Metals '18

* Register Now: Hi-Tech Metals '18

* Call for Papers: Computational Modelling '19

* Call for Papers: Physical Separation '19

* First Announcement: Flotation '19

* First Announcement: Comminution '20

* First Announcement: Biomining '20

* First Announcement: Sustainable Minerals '20

| Here at MEI, we're gearing up to travel to Cape Town for Process Mineralogy '18 and Hi-Tech Metals '18. Both events take place at the wonderful Vineyard Hotel, with Process Mineralogy taking place at the start of the week (Nov. 19-21) and followed straight after by Hi-Tech Metals (Nov. 22-23). Process Mineralogy features an exhibition, and we have 2 booths left if you're interested, just contact Jon for details. |

Looking ahead to 2020, ME Elecmetal are sponsoring Comminution '20 for the first time, although with 18 months still to go before the event, they are already the 9th sponsor! It looks like Comminution '20 is on course to be as popular as ever.

As mentioned in the last newsletter, we are trying to build our subscriber list back up. If you wish to be added to the list for future newsletters, please let me know.

Barry's Blog:

* High capacity microwave treatment of ores may be closer than previously thought

* Cornwall's greatest copper mine in the 'richest square mile on earth'

* Kemtec and ME Elecmetal: the latest companies to confirm sponsorship of MEI Conferences

* An appreciation of Prof. TC Rao

* Welcoming two new sponsors for Physical Separation '19: TOMRA and Outotec

* AusIMM Complex Orebodies 2018: Register Now

* Drakelands Mine, the hot topic at the October Mining Sundowner

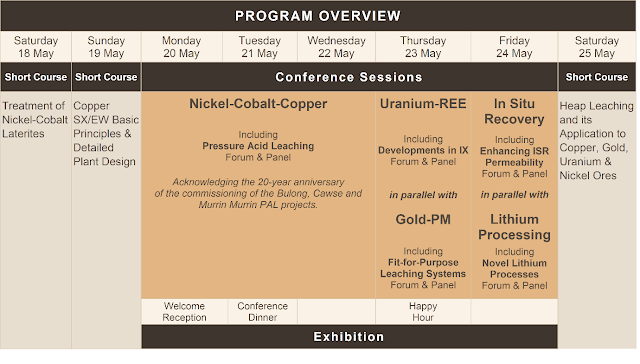

* ALTA 2019

* It's official: Prof TC Rao is the "Father of Indian Minerals Engineering"

* A brief but enlightening visit to China's Central South University

* The Environmental Applications of Biotechnology in Mining

* Fathi Habashi- still going strong at 90 years of age

* A legendary steam engine passes through Cornwall

* Cornwall's Coast to Coast Mining Trail

* High capacity microwave treatment of ores may be closer than previously thought

* Cornwall's greatest copper mine in the 'richest square mile on earth'

* Kemtec and ME Elecmetal: the latest companies to confirm sponsorship of MEI Conferences

* An appreciation of Prof. TC Rao

* Welcoming two new sponsors for Physical Separation '19: TOMRA and Outotec

* AusIMM Complex Orebodies 2018: Register Now

* Drakelands Mine, the hot topic at the October Mining Sundowner

* ALTA 2019

* It's official: Prof TC Rao is the "Father of Indian Minerals Engineering"

* A brief but enlightening visit to China's Central South University

* The Environmental Applications of Biotechnology in Mining

* Fathi Habashi- still going strong at 90 years of age

* A legendary steam engine passes through Cornwall

* Cornwall's Coast to Coast Mining Trail

Analytical Techniques & Applied Mineralogy

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

* Technical Programme: Process Mineralogy '18

* Register Now: Process Mineralogy '18

* Recently Refereed Publications:

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Analytical Techniques & Applied Mineralogy is sponsored by FEI

Biotechnology

~~~~~~~~~

* First Announcement: Biomining '20

* The Environmental Applications of Biotechnology in Mining

* Recently Refereed Publication:

Minerals Engineering Vol.126

Comminution

~~~~~~~~~

* First Announcement: Comminution '20

* Peak Performance from Metso's new Superior MKIII Primary Gyratory Crusher

* Metso to Deliver Comminution and Material Handling Solutions to Australia and South America

* Conference Announcement: ESCC 2019

* Recently Refereed Publications:

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Powder Technology Vol.337

Comminution is sponsored by Russell Mineral Equipment

Computer Applications

~~~~~~~~~~~~~~~

* Call for Papers: Computational Modelling '19

* Recently Refereed Publications:

Powder Technology Vol.338

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Powder Technology Vol.337

Environmental Issues

~~~~~~~~~~~~~~

* First Announcement: Sustainable Minerals '20

* Technical Programme: Hi-Tech Metals '18

* Register Now: Hi-Tech Metals '18

* Conference Announcement: The 9th International Conference on Sustainable Development in the Minerals Industry

* The Environmental Applications of Biotechnology in Mining

* Recently Refereed Publications:

Minerals Engineering Vol.126

Separation and Purification Technology Vol.206

Minerals Engineering Vol.125

Froth Flotation

~~~~~~~~~~

* First Announcement: Flotation '19

* World’s Largest Flotation Cells Improve Copper and Molybdenum Recovery in Mexico

* Are Conditioning Tanks Making A Comeback?

* Commencement of Flotation Commissioning at the Hellyer Polymetallic Project, Tasmania

* Recently Refereed Publications:

Powder Technology Vol.338

Minerals Engineering Vol.126

Separation and Purification Technology Vol.206

Colloids and Surfaces A: Physicochemical and Engineering Aspects Vol.555

Chemical Engineering Journal Vol.351

Minerals Engineering Vol.125

Froth Flotation is sponsored by FLSmidth

General Minerals Engineering

~~~~~~~~~~~~~~~~~~~

* Technical Programme: Hi-Tech Metals '18

* Register Now: Hi-Tech Metals '18

* Conference Announcement: MetPlant 2019

* Conference Announcement: IMPC 2020

* Conference Announcement: COM 2019

* Conference Report: 2nd Young Nonferrous Metals Scientists & Engineers Forum

* High Capacity Microwave Treatment of Ores may be Closer than we Thought

* CIM Awards - Call for Nominations

* Eriez Europe Expands With New Manufacturing Facility

* ArcelorMittal Mining Canada G.P. to Fund Major Mining Research Collaboration at McGill University

* Recently Refereed Publications:

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Gravity Concentration

~~~~~~~~~~~~~~

* Call for Papers: Physical Separation '19

* Tempo Mineral Processing Offers DMS Cyclone Refurbishment Service

* Recently Refereed Publications:

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Hydrometallurgy

~~~~~~~~~~~

* First Announcement: Biomining '20

* The Environmental Applications of Biotechnology in Mining

* Lithium Ion Exchange Provides a New Source for Battery Materials

* Recently Refereed Publications:

Chemical Engineering Journal Vol.354

Minerals Engineering Vol.126

Separation and Purification Technology Vol.207

Minerals Engineering Vol.125

Chemical Engineering Science

Journal of Cleaner Production Vol.197

Magnetic/Electrical Separation

~~~~~~~~~~~~~~~~~~~~

* Call for Papers: Physical Separation '19

* Innord Approved for Conditional Funding from the National Research Council of Canada

* Recently Refereed Publications:

Minerals Engineering Vol.126

Minerals Engineering Vol.125

Materials Handling

~~~~~~~~~~~~

* Recently Refereed Publication:

Powder Technology Vol.338

Pyrometallurgy

~~~~~~~~~~~~

* RNC's Innovative Roasting Approach Delivers 25% Increase In Payable Nickel Value For Nickel Sulphide Concentrates

Reagents

~~~~~~

* AkzoNobel Specialty Chemicals is now Nouryon

* Recently Refereed Publications:

Powder Technology Vol.338

Minerals Engineering Vol.126

Separation and Purification Technology Vol.207

Minerals Engineering Vol.125

Reagents is sponsored by Axis House

Sizing, Classification & Sorting

~~~~~~~~~~~~~~~~~~~~

* Call for Papers: Physical Separation '19

* TOMRA Enhances X-TRACT with Dual Processing Technology, Multi-Density Channels, and Application Packages

* Large New TOMRA X-ray Sorter

* Recently Refereed Publications:

Powder Technology Vol.338

Minerals Engineering Vol.126

Separation and Purification Technology Vol.206

Solid-Liquid Separation

~~~~~~~~~~~~~~~

* Call for Papers: Physical Separation '19

Solid-Liquid Separation is sponsored by FLSmidth

Plant Operations

~~~~~~~~~~~

* Investment in Leaching Plant at Boliden Rönnskär

* World’s Largest Flotation Cells Improve Copper and Molybdenum Recovery in Mexico

* First Aachen Shear Reactor for Turkey

* BacTech Attracts Ecuador Partner for Ponce Enriquez Project

* Mineworx Provides Update on E-Waste Concentration Plant

* Multotec Samplers Give Real-Time Results at Gamsberg

* Metso to Deliver Beneficiation Solutions for Potash Industry in Belarus

* China's Western Mining to Launch Qinghai Copper Smelter Next Month

Plant Operations News Australasia is sponsored by Magotteaux

Plant Operations News Europe is sponsored by Holman-Wilfley

People News

~~~~~~~~

* Prof. Yuehua Hu Elected to Editorial Advisory Board of Minerals Engineering

* Prof. TC Rao Honoured as the “Father of Indian Minerals Engineering”

* Leagold Appoints Attie Roux as Chief Operating Officer

* A Brief but Enlightening Visit to China's Central South University

* 2018 CEEC Medal Winners Recognised At AusIMM Conference

* MEI's Barry Wills Appointed Honorary Professor of Central South University, China

* New Vice President of Technical Services for Canada’s Hudbay Minerals

* New Gold Announces Appointment of President and CEO

* J. Burgess Winter 1933-2018

* Major IMPC Awards to Two Distinguished American Professors

* IMA Medal of Excellence in Mineralogical Services 2017 goes to Emil Makovicky

* John Van Nostrand Dorr joins the IM Technology Hall of Fame: Concentration

Join the Minerals Engineers LinkedIn Group

People News Australia is sponsored by JKMRC & JKTech

Commodities

~~~~~~~~~

New items in:

* Calcium Carbonate - Refereed Publications

* Cobalt - Refereed Publications

* Copper - News

* Copper - Conference Announcements

* Copper - Refereed Publications

* Gold - News

* Gold - Refereed Publications

* Iron - Conference Announcements

* Iron - Refereed Publications

* Kaolin - Refereed Publications

* Lithium - News

* Lithium - Refereed Publications

* Manganese - Refereed Publications

* Nickel - News

* Nickel - Refereed Publications

* Platinum Group Metals - Refereed Publications

* Potash - News

* Quartz - Refereed Publications

* Rare Earths & Thorium - News

* Rare Earths & Thorium - Refereed Publications

* Titanium - Refereed Publications

* Tungsten - Refereed Publications

* Vanadium - Refereed Publications

* Zinc - Refereed Publications

Minerals Engineering Conferences

~~~~~~~~~~~~~~~~~~~~~~

* Technical Programme: Process Mineralogy '18

* Register Now: Process Mineralogy '18

* Technical Programme: Hi-Tech Metals '18

* Register Now: Hi-Tech Metals '18

* Call for Papers: Computational Modelling '19

* Call for Papers: Physical Separation '19

* First Announcement: Flotation '19

* First Announcement: Comminution '20

* First Announcement: Biomining '20

* First Announcement: Sustainable Minerals '20