Tuesday 10th May

Magnetic Separation was the theme of the first session this morning, with three presentations, starting with a keynote lecture from Neil Rowson, Emeritus Professor of Minerals Engineering at the University of Birmingham, and Laboratory Manager at Bunting-Redditch. Neil gave an overview of the role of magnetic separation in the development of critical and strategic metal recovery flowsheets (see posting of 25 October 2021).

|

| Neil Rowson (left) at Physical Separation '19 |

Following the keynote, George Abaka-Wood, of the University of South Australia, presented a study where mineralogical and strategic beneficiation tests were undertaken on complex low grade saprolite ore to assess the feasibility of recovering valuable rare earth elements minerals as by-products of gold leaching by magnetic separation.

Panagiotis Angelopoulos of the National Technical University of Athens, Greece, then discussed the two-stage processing of bauxite residue towards the recovery of residual Al and the production of Fe- and REE-rich concentrates through magnetic separation.

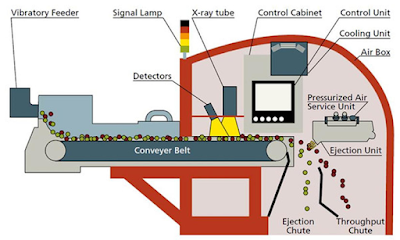

Electronic sorting was the theme of the afternoon session. It is ironic that sorting, once a major method of concentrating ores by hand, became effectively redundant, but is now enjoying a very strong resurgence thanks to high speed computers which allow pre-concentration of ores at very high rates, reducing comminution energy and water costs.

|

| Typical sensor-based sorter |

Conference sponsor Steinert is a major player in this field and there were two presentations from Steinert Latinoamericana, Brazil this afternoon. Priscila Esteves, who will be a representative on the panel discussion tomorrow, discussed the applicability of sensor-based sorting technology for improving the quality of Brazilian iron ore lump. The iron ore industry faces the transition to low grade deposits with increasing pressure for a more sustainable approach. There is increasing importance for concentration methods that can improve quality of lump material and sensor-based sorting technology is an option for increasing lump quality by applying a low cost and dry beneficiation technique.

Edwardes Dias, head of Customer Support for Steinert Latin America, explained how sensor based sorting technology has been used to separate chromite lump from low grade rocks for the past seven years in the northeast of Brazil, replacing a hand-picking operation. He discussed how data analysis on chromite rock scans has been used to assist the improvement of a sensor- based sorting algorithm.

TOMRA is also a major manufacturer of electronic sorting machines, and TOMRA sensor-based particle ore sorting has been in operation since 2015 at the San Rafael tin mine in Peru for pre-concentration of hard rock cassiterite ore. Aysa Moslemiyekan, of SIX-S GmbH Consulting, Germany, described a new methodology and results from a simulation developed to further optimize the particle ore sorting plant.

Modern electronic sorters employ sensors to distinguish differences in various properties of rocks, and Beichen Duan, of the University of Toronto, Canada, presented an interesting study to investigate if microwave imaging (MWI) can be used to distinguish rocks that contain valuable minerals or metals from those that do not, for potential application as a new sensing method. Compared to more established sensors MWI has the potential to penetrate deeper into ore particles and to analyse those ores with high contrast in electromagnetic properties between valuable minerals/metals and gangue minerals.

In another presentation from Canada, Patrick Mercier, of COREM, explained that ore sorter manufacturers typically provide technology evaluation by carrying out production tests using 50 to 5,000 kg of feed material. Whereas the resulting cumulative mass pull-recovery curves obtained for such pilot-scale tests provide a quantitative estimate of the expected ore sorting performance, their potential uncertainty, due to, for example, feed composition variability, is not assessed. Patrick presented a methodology to cross-validate pilot-scale results against bench-scale amenability testing on a sub-sample of rocks hand-picked from the ore feed, demonstrating how to forecast the variability of sorting performance at scale fora given ore type over a range of feed compositions expected during sorter operations.

Today has been another interesting day of presentations, all of which are available on demand for the next 6 months.

Thank you Aysa for a great article and presentation on simulating ore sorting.

ReplyDeleteChristopher Robben, SIX-S GmbH, Germany (via LinkedIn)

Prof. Rowson's presentation is really comprehensive. I would like to thank you Prof. Rowson and MEI for delivering this key speech.

ReplyDeleteMahmut Camalan