I need very little excuse to visit the King Edward Mine (KEM) Museum in Camborne. It is only 12 miles from Falmouth, and is without doubt one of the world's finest mining museums, and an absolute must for anyone interested in early mining industry. There are very few, if any, places in the world where you can see 19th century gravity concentrators, such as round frames, buddles, Frue Vanners and rag frames, in operation.

Yesterday there was a very well attended Open Day and it was good to catch up with many of our sundowner regulars who are volunteers and give their free time to developing the site and to acting as knowledgeable guides.

KEM is the oldest complete mine site left in Cornwall. The mine was formerly part of South Condurrow Mine, which was abandoned in 1896. Re-opened and developed as a fully operational/training mine by the Camborne School of Mines (CSM), KEM was used up to the mid 1970s when the mill became a store. In 1987 a volunteer group was formed who restored the mill using rescued machinery.

The star attractions in the mill, which simulates operations much as they would have been in the early years of last century, are the Californian Stamps and the Rag Frames, and Carol Richards, a Director of Camborne School of Mines (CSM) Association and a long-term KEM volunteer, has produced two excellent videos showing the stamps and the rag frames in operation.

|

| Carol Richards |

The stamp battery at KEM is very small, but visitors are always impressed by the deafening noise, which gives some impression of what the now tranquil scene outside KEM must once have been like. The Museum is in the centre of the Camborne mining district, surrounded by ruined engine houses, some of which drove huge stamp batteries. With the engine houses spewing flame and black smoke from their chimneys, amidst a background of the continuous drum of the stamps, the nearby villages could not have beeen described as prime real estate, and it is pretty obvious that licence to operate was not a major consideration in those days.

Rag frames were simple but effective machines, their operation being shown clearly in Carol's video. Like round frames, they were used for the automatic treatment of fine cassiterite slimes, and were developed from hand-operated wooden frames, tended by girls, or bal maidens, which were in use for well over 100 years, until the 1860s.

|

| Bal maidens by the rag frames at Wheal Grenville, adjacent to KEM, c1900 |

|

| Rag frames at the Dolcoath mine, Camborne, in the 1890s |

|

| Physical Separation '13 delegates by the rag frames |

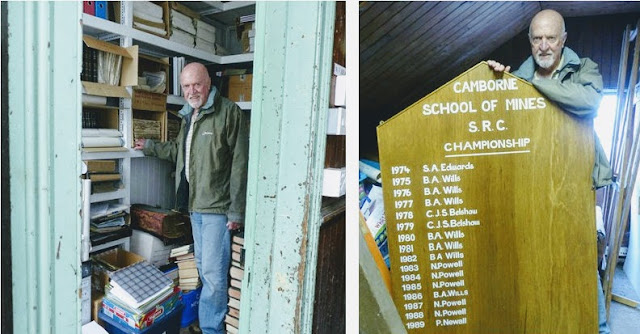

My visits to KEM are also tinged with nostalgia as it was here that I spent my first few months at CSM from late 1974 until the move to the new premises between Camborne and Redruth in 1975. My first office at CSM was an old broom cupboard in the KEM Survey Office, and laboratory practical sessions were carried out on the disparate pieces of equipment which were in what is now the museum's mill, which was piercingly cold in winter. Not too far away, in the centre of Camborne, was the student union and squash courts, and it was great to see the old squash honours board yesterday, which has recently been found after all those years.

Thanks to everyone at CSM for a great day out yesterday.

|

| In my old office, and the recovered CSM squash club honours board |

Twitter @barrywills

Great museum, well worth the visit for a processing engineer. Barb and I visited twice last fall during an extended stay in Cornwall and came away with some videos of processes ancient being run by the staff. Add in the exhibits with pictures and they supplied some real context around the mill site foundations we hiked about.

ReplyDeleteThanks,

Bob

Yes, it is a great museum, particularly for processing. Not quite sure who you are though, Bob?

DeleteGreat video.

ReplyDeleteNot too strangely, I now have memories of Richard Mozley.

The museum is now on the 'must do' list

Many thanks

Craig Brown

Nice to read such history on one of the places where mineral processing was practiced with those kind of units; good that it is still kept as a museum.

ReplyDeleteA point to note is that an Educational Institute took over the abandoned mine for training of students; shows importance given for trining.

Reminds me of Prof.F.T.M. White , HOD of Mining Engineering at Queensland University taking over an abandoned mine at Indoorpilly in early 1960s to train students . Dr.A.J.Lynch, another visionary and legend built a world class research Centre around that experimental mine which is now J.K.Centre.

Barry, thanks a lot for the narrative;--history has so much to teach.

Thank you Professor Rao for your kind comment about my father's seminal role in the rehabilitation of the old silver-lead mine at Indooroopilly and developing it into a first class educational, research and development site for the University of Queensland. As sole remaining member of his immediate family, this is appreciated. For the historical record, that effort started in 1951 and continued under his leadership until 1965-66, when he relocated to McGill University (Montreal), to catalyse redevelopment of North America's oldest school of mines. Unfortunately he passed away in 1971 at the age of 62, before he could fulfill all aspects of his vision for that institution. This said, in my opinion, the work he did at Indooroopilly represented the height of his career: he was passionate about the future of the minerals industry, and highly effective in communicating this not only to his colleagues and students, but to society at large. It may be of interest to MEI participants that, in my retirement from an extensive public health career (which has had some overlaps with the minerals industry in several countries), I am now working on a biography of his life and career. My thanks also to Barry Wills for maintaining this marvellous blog, which is proving to be a valuable source of inspiration for this project.

ReplyDeleteMany thanks for this Franklin. Now I know exactly who you are thanks to Prof. Rao's comment. Highlights my post of 2nd May - it is good to talk! And many thanks also for your kind comments on the blog

DeleteAnd keep me updated on the biography.I will put something on blog

DeleteI will be pleased to let you know once the FTM White biography project is published Barry, most likely in an eBook format. At this stage it is still very much a work in progress, and I have no set timetable for its completion or release. However, by way of a thumbnail sketch for which I have made substantive inputs, there is an abbreviated bio on Wikipedia that may be of interest to readers: https://en.wikipedia.org/wiki/Frank_T._M._White

ReplyDeleteInteresting person. Thanks Franklin

DeleteFranklin,

ReplyDeleteSo nice to see your remarks,

Prof. White made my career. I just applied for admit ion for a Ph.D. program in the year 1951 at U.Q.from India; he was a visionary--must have thought that Mining Dept needs an Indian. He offered a teaching fellowship and I landed in Brisbane on a Sunday evening, Prof.White came to airport to receive me(I was looking and feeling lost because that was the first time I traveled by a plane to a unknown country(at that time to me)--put me in a hostel---I can go on and on about Prof.White. More of a GOOD HUMAN BEING above his visionary actions I said all this while taking my "best alumni award" given

by U.Q. to me in 1998.

He changed my life.

Barry also mentioned all this in one of his Blogs on me.

I have no words to express more--

God Bless You.

Dear Professor Rao:

ReplyDeleteThanks for your additional kind comments about my late father. It would have been 1961 when you first landed in Brisbane, and I suspect that we personally met around that time (I was in my mid-teens), as my parents took pleasure in hosting overseas students at our home and your arrival as the first such student from India would have been a very special occasion. It is warming to think of him primarily as a good human being; thank you for for those words.

Yes, it was 1961--now I have to start admiring you for your memory --worthy son to a worthy Father.

ReplyDeleteLet me thank Barry also for providing this platform which brought all those sweet memories about such a visionary like Prof.White.

Really great to see such extinct units of Mineral Processing which were i hope the best or basic separation units. Till working in some places in bits and pieces. Appreciate the efforts to keep Mineral processing alive like it was never old.

ReplyDeleteCheers to 06 times champion Dr. Barry holding the board of championship....

Great to see always such historic units which i hope we can't see anywhere else.

Thanks and regards

Rama Murthy

In fact that's great to see Dr Rao, my mentor here in India. The experiences he shares with me is now visible on this site and great to see all thing which are beyond imagination.

ReplyDelete